Safety Consulting & Advisory

- Document control sheets give revision status and controlled distribution of the safety case and associated studies.

- Summary & Introduction give background, values of risk indicators and the case for continued operation. The organisation of the safety case structure is discussed and compliance with regulations is shown. Summaries of duty holder details and life extension studies are given. References are listed.

- HSE Management System summarises HSE Policy, the HSE organisation, the main elements in the HSE management system and how they are implemented effectively and measurably at the workplaces. The Health, Safety and Environment Management System (HSEMS) processes are geared to identify, assess, control and recover from hazards.

- Installation Description gives the Major Accident Hazard (MAH) environment and inventories on a facility, the Evacuation Escape and Rescue (EER) and Life Saving Appliances (LSA) arrangements, areas for personnel congregation, hazardous areas, H2S Zones and TPB zoning. Maps of the natural environment are given and interaction with other facilities is identified.

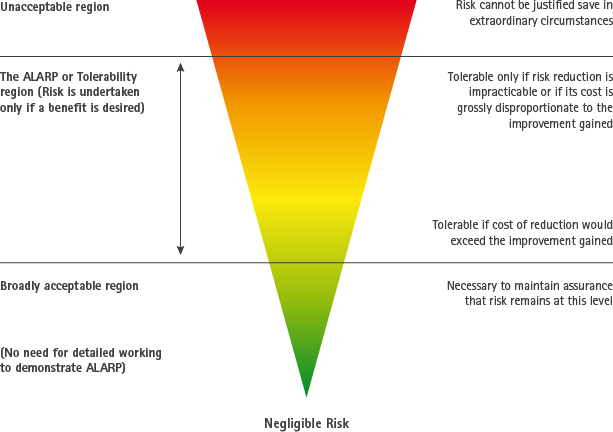

- Major Accident Hazard (MAH) Identification, Assessment & Management details identification, assessment and risk ranking of hazards, evaluation of risks to personnel (onsite & offsite) and environment, the identification of Safety Critical Element (SCE) requirements, assurance of established levels of safety and environmental soundness, demonstration of ALARP status and thus the case for continued operation.

- Emergency Response Plans are summarised and derive the Emergency Response Plan (ERP) and Critical Path Method (CMP) from Emergency Response Scenarios. The safety of the Emmergency Response (ER) effort is demonstrated via consequence modeling of the ER scenarios.

- Appendices and Associated Studies:

- Management of hazards describes the process and systems in the HSEMS for identifying; assessing, preventing and recovery from hazards at the workplace. It also gives an analysis of the HSEMS.

- Hazard Identification: starting from a generic hazard checklist, part 5B identifies all MAHs identified for the installation. A discussion of non MAH hazards is included to ensure a conservative approach.

- Emergency Systems Survivability Assessment establishes whether the EmmergencySystem(ES) can fulfil their designated role during the parent Major Accident Event (MAE).

- Fire Consequence Analysis details process and non-process fires, riser fires and blowouts. The impact on EER facilities is assessed.

- Explosion Consequence Analysis details explosion scenarios, modeling methods and loading results. Survivability and impact to primary and secondary structures and EER facilities is assessed.

- Smoke & Gas Ingress Analysis details smoke and gas migration, which can impair escape routes, TRs and muster points.

- Toxic Hazard Analysis details zoning requirements and assesses the impact on personnel, environment and EER facilities.

- Collision Hazards assesses ship and aircraft collisions. Passing and attendant vessels are collisions during tanker loading are assessed.

- Dropped Object Study: assesses consequences to structural and containment systems. Escalation effects are addressed.

- External Loads: studies consequences of extremes in the natural environment including moving ice and global warming.

- TR and Escape, Evacuation and Rescue Assessment (EERA) Analysis assess the performance of EER systems during MAHs and provide input to the Quantitative Risk Analysis (QRA).

- SCEs and Performance Standards Assessment identifies Health, Safety and Environmental Critical Equipment System (HSECES) required by code. The link between MAH and PS is established, and performance standards are summarised. Suitability and sufficiency is demonstrated and Written Scheme of Verification (WSV) summarised.

- QRA: The Quantitative Risk Analysis reports are included.

- Assessment of MAHs: assessment results for all MAHs, including Potential Loss of Life (PLL) and Total Recordable Incident Frequency (TRIF) results (where required) will be presented

- ALARP Demonstration: The ALARP (As Low As Reasonably Practical) process is described, the QRA results are reviewed to determine if residual risks are ALARP and the provision of HSECES are suitable and sufficient.

- Continuous Improvement discusses Risk Reduction Measures (RRMs) reviewed, implemented and those under consideration at the time of Safety Case preparation.

- Conclusion: examines risk assessment results, safety critical elements (SCE) and loss prevention arrangements – and argues the case for construction, continued operation, combined operation or decommissioning and abandonment.

Escape, Evacuation and Rescue Analysis (EERA)

Petroka is experienced in leading EERA Studies to assess EER facilities. Justification for the EER design is made through assessing distribution, functionality, diversity, capacity, endurance and the risks to personnel in oil and gas emergency response scenarios.

Impairment of EER facilities occurs if performance requirements are not met. The requirement is to ensure that the Emergency Response Team have procedures to allow personnel to:

- Leave the worksite safely and can access their Muster Point.

- Evacuate site and reach safety with minimum risk.

- Be rescued safely, if required

Defining Emergency Response Scenarios

As a preparation step for the Emergency Response Plan, Petroka ensure that a link between the MAHs and the Emergency Response function is established. Defining Emergency Response Scenarios through analyzing the consequences of a MAH, ensures that the Emergency Response Procedure is effective, proportionate, staged, escalated correctly and can be carried out safely. We carry out an Emergency System Survivability Assessment (ESSA) to determine the survivability of oil and gas emergency systems during a MAH. Recommendations from ESSA ensure the required level of redundancy is provided in the Emergency System.

Each oil and gas Emergency System is assigned a Vulnerability Index as per our work practices.

Emergency Response Plans

We are experienced in analyzing onsite and offsite Emergency Response Plans for compliance with codes of practice and legislation, providing recommendations to ensure:

- There are links between the parent MAH, consequence modeling, the Emergency Response Scenario, the ERP and the ER equipment.

- There remains an adequately manned Emergency Response Team at the facility based upon day, night and weekend shift patterns.

- Emergency Response communications are suitable and sufficient.

- Onshore Response Centre facilities and Crisis Management Plans are suitable with distribution to the wider Emergency Response providers.

- Provisions for training of Emergency Response Team personnel and Onshore Response Centre through exercises and drills.

Petroka offer Process Hazard Analysis (PHA) studies including Hazard and Operability (HAZOP) and Hazard Identification (HAZID) as part of risk analysis process detailed in IEC 61508 / IEC 61511 (Phase 1)

Petroka’s consultants provide Safety Integrity Level (SIL) Verification studies, assessing the SIL capability of specified Safety Instrumented Functions (SIFs), using methods such as Fault Tree Analysis (FTA), Reliability Block Diagrams (RBDs) or Failure Modes Effects and Criticality Analysis (FMECA).

Petroka have experienced SIL Determination consultants that lead and facilitate studies from calibrated Risk Graphs, to semi-quantitative Layers of Protection Analysis (LOPA) and fully-quantitative Fault Tree Analysis.

Petroka is able to setup Functional Safety Management (FSM) Systems and undertake third party audits on existing procedures and techniques for compliance against recognized international safety standards including IEC 61508, IEC 61511 and IEC 62061.

Quantitative Risk Assessment (QRA) is a formalized and systematic tool for quantifying the risks associated with the operation of an engineering process. A QRA is essential to assessing the risk exposure to employees, the environment, company assets and its reputation.