Availability & Reliability

FMEA identifies the potential failure modes of a component in systems, their causes and their effects on these systems, the safeguards already incorporated and the potential additional mitigation measures that could be considered. In addition, an FMEA includes a qualitative assessment of the severity and probability of occurrence of each failure mode. In other words, it is a methodology to identify, prioritize, and eliminate potential failures from the system.

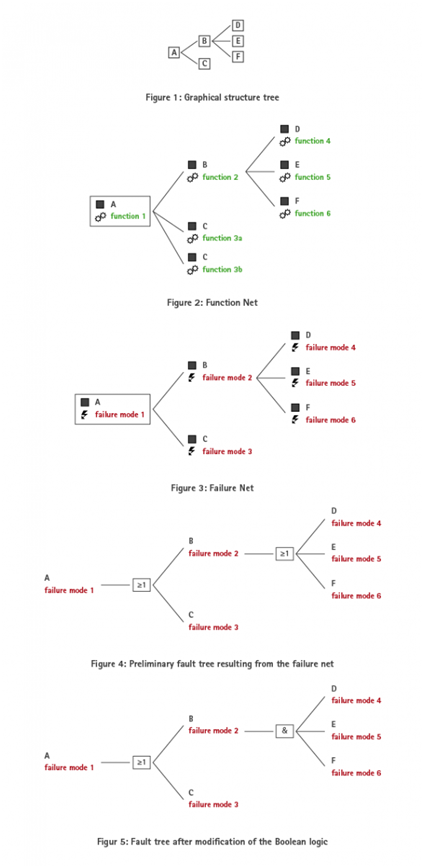

An FMECA is similar to an FMEA, except that the severity and probability of occurrence of each failure mode are assessed quantitatively rather than qualitatively. These analyses are presented in a spreadsheet (worksheet) format. Traditionally, the spreadsheet was filled out directly, and it was always difficult to be sure whether the study was truly systematic. However, Petroka has developed a highly structured approach to the performance of FMEA/FMECA that increases confidence that important issues have been captured. This is achieved by carrying out a number of preliminary steps, including the preparation of a component relationship diagram, a function net for each system function and a failure net for each system failure mode. All data is input for the relevant diagrams and finally the FMEA/FMECA spreadsheet is generated automatically by software from the various diagrams.

In order to ensure that all potential failures have been considered and proper provisions have been made for failure elimination, the analysis should be performed during the conceptual/FEED design phase of the system, where we are able to provide the greatest impact on the system reliability.

FMEA/FMECA can be applied as a precursor to a FTA/RAM Analysis or a Quantitative Risk Assessment (QRA), or as a standalone study.

FMECA usually results in risk being reduced by introducing:

- Design alterations/ reconfigurations.

- New and innovative safety functions.

- Detection and safety devices.

- Failure elimination.

- Criticality analysis.

- Systems and procedures.

- Training of personnel.

The findings of the FMECA are applied to, and generally add value to:

- Maintenance plans.

- Manufacturing plans.

- High reliability design selection.

- Systems and equipment operations.

- Requirements for test equipment’s and planning.

- Considerations in future design changes.

To discuss your requirement please contact us at info@petroka.com

FTA and Event Tree Analysis (ETA) are methods of calculating the probability of hazardous scenarios from the failure rate of causal events – root cause analysis (RCA). Often, what we are attempting to establish is the top event; Probability of Failure on Demand (PFD); e.g. the probability that a High Integrity Pressure Protection System (HIPPS) valve would not close on demand. FTA can be applied in a wide variety of ways, some of which include:

- To perform Safety Integrity Level (SIL) validation.

- To calculate the reliability of a system that has to operate on demand, e.g. quick release mechanisms, emergency shutdown systems, firewater systems and high integrity pressure protection systems (HIPPS).

- To calculate the initiating event for an Event Tree Analysis (ETA), e.g. as part of the Quantitative Risk Assessment.

- To calculate reliability of components such as valves and connectors from reliability data relating to their component parts.

- To calculate the likelihood of a particular hazardous scenario in terms of the likelihoods of equipment failures and human errors leading up to it.

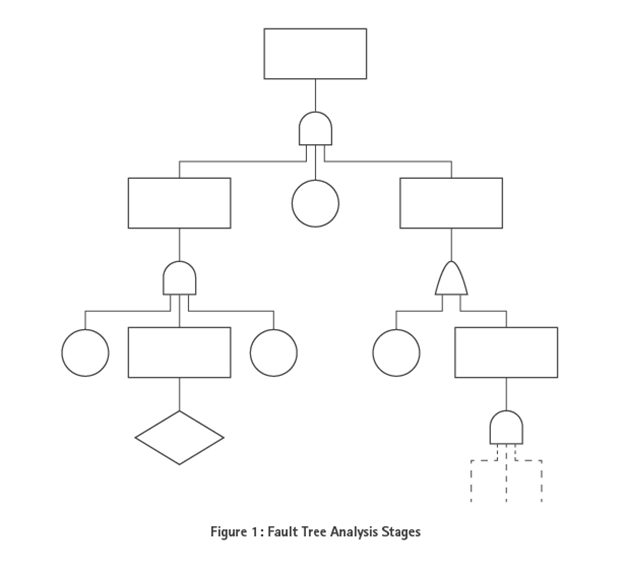

FTA is a defined, structured and rigorous visual tool that displays the logic interfaces of components within a system, including redundancies and common cause failures. It utilizes Boolean algebra probability and reliability theory. It is built up by logic AND and OR gates and provides great flexibility in studying:

- Best configuration for a system.

- Required component reliability to achieve pre-defined PFD.

- Optimum voting (XooY) for sub-systems instrumentation.

- Optimum redundancy for components.

- Optimum testing intervals.

FTA is thus applicable for many types of analyses in our industry; for safety, reliability, availability, maintenance optimization and accident investigation. There is a strong link to Root Cause Analysis (RCA). In most cases we recommend performing FMECA prior to performing FTA, unless the system is simple.

To know more or discuss FTA and related subjects, please contact us at info@petroka.com

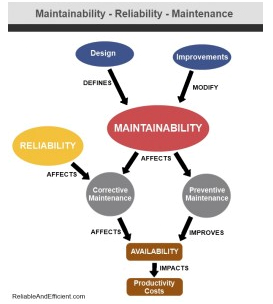

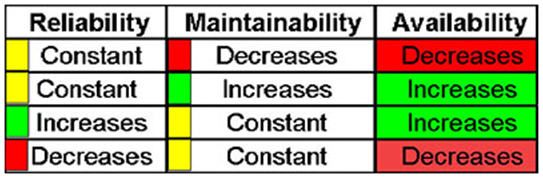

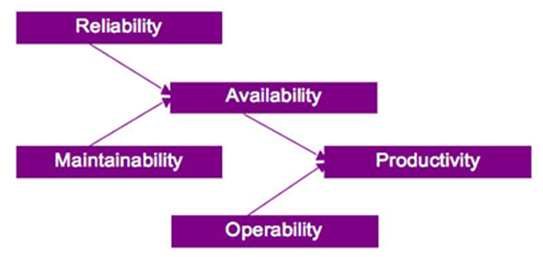

RAM Studies are used as a way of assessing a production system’s capabilities, both in operation and those still in the design phase. As facilities and plants are being used for longer period of time, a Reliability, Availability and Maintainability Study is able to provide an assessment into the assets life time capabilities and enable businesses to maximize on their return on investment.

A RAM Study can be shown to be broken up into three separate areas:

- Reliability Services – Predicting the probability in which a system will not experience an unplanned outage.

- Availability Services – Predicting the probability in which the system is working in a functioning state when required, including both planned and unplanned outages.

- Maintainability Services – Predicting the probability in which a product / system can be repaired following a failure within a specific time frame.

With the combination of these three services combines into one study, Petroka is able to offer a RAM Study that models the predicted production capabilities of a facility.

The benefits of undertaking a RAM Studies include:

- A reduction in the maintenance and sparing costs, while maintaining and / or increasing production levels.

- A decrease in the duration of any unplanned and planned outages.

- Optimisation on capital investment by reducing the cost of production.

- Optimisation of capital improvement options at the plant and enterprise levels when improve budgets are constrained.

- Accurate forecasts of equipment lifecycle costs that reflect the equipment age, duty cycle and maintenance effectiveness.

- Alignment of maintenance resources based on the criticality of equipment to production revenue.

Petroka has a number of Reliability Consultants that have worked on an extensive range of projects across a number of industries. In choosing Petroka to conduct your RAM Studies, Petroka’s specialist RAM Studies Consultants are able to:

- Produce a RAM Study customized based on the needs and requirements of the client.

- Identify potential critical pieces of equipment.

- Identify the equipment that has the highest risk of causing operational failures.

- Identify possible causes of production losses and examine the possible alternatives to overcome them.

- Produce Reliability Block Diagrams (RBDs) with the aid of SIL Comp®.

- Produce a RAM Study based on different system configurations.

- Produce recommendations on how to improve the system availability.

- Produce a record of the RAM Study in the form of a formal report, detailing an overview of the RAM Study, including any assumptions made as well as the findings as part of the study.

As well as offering RAM Studies, Petroka is also able to additionally offer a Cost Benefit Analysis (CBA) as part of the RAM Study.

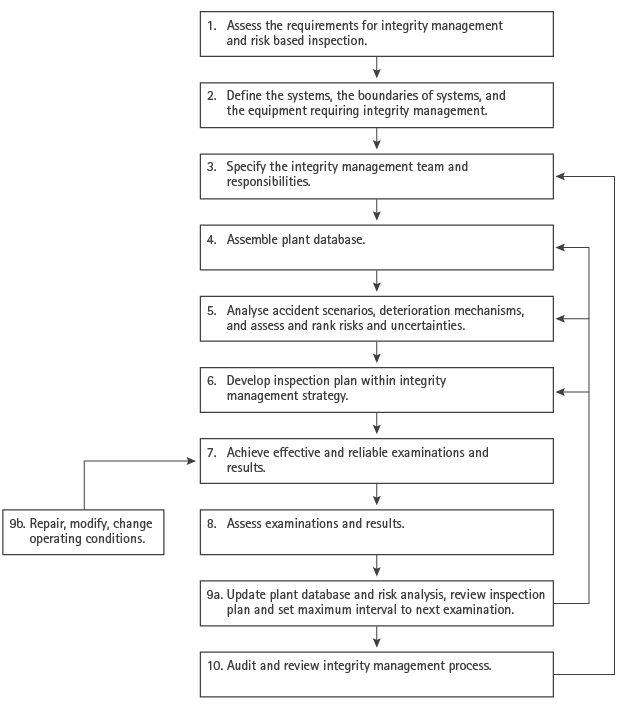

Risk Based Inspection (RBI) is a risk based approach to planning plant inspections, for optimum plant maintenance. It is a systematic technique focused at achieving optimum asset integrity management and system integrity. With RBI, there is the outlook for future savings in cost emanating from the optimal use of resources.

Savings arise from modified/ reduced direct inspection costs.

RBI program techniques focus inspection resources on parts of the plant where they will have the greatest benefit, and hence result in reduced downtime. In line with the principles of ALARP (As Low As Reasonably Practicable), RBI aids prioritizing of resources for equipment with higher probabilities of failure. Because RBI focuses on the critical equipment and identifies priorities for inspection based on the risk of failure, it introduces additional safety benefits for the system.

The effectiveness of the RBI program is dependent on the accuracy of the reliability analysis and risk assessment data used, and the RBI reviews and audits.

It is now widely accepted that the traditional time-based approach to planned plant inspection by a competent person has a number of shortcomings. In particular, the use of fixed intervals between inspections may be too conservative and lacks the freedom to benefit from good operating experience.

Petroka employs the highest standards in our RBI study methodology e.g. API RP 580 and API RP 581.

Good quality information and the correct interpretation of data are essential for the relative accuracy of RBI analyses. Central to valid RBI methods is the correct identification of damage mechanisms, failure modes and conditions that bring on deterioration. See also FMECA.

As part of our best practices for RBI programs, all plant maintenance data gathered will be subject to review and validation by our competent consultants nominated for a specific study before being established in the Data Manual for use.

Central to defining risk levels associated with the failure of a piece of equipment is determining the probability of failure and the consequences of failure of each identified item of mechanical equipment, or piping, that may lead to a critical event. Our RBI study methodology includes the consideration of the probability of failure and its consequences usually in a probability-consequence matrix.

The risk ranking resulting from the probability-consequence matrix is thus used to prioritize and plan the Inspection of equipment’s within a process unit. As the risk ranking is a direct function of the active and potential damage mechanisms that can cause a release – and the damage rate associated with it – it follows that the plant inspection priorities are based on the specific risk of failure. See also reliability centred maintenance.

We use the information from the damage rate data and the value of the inspection to determine the period to the next risk based inspection.

To discuss your challenges please contact us at info@petroka.com

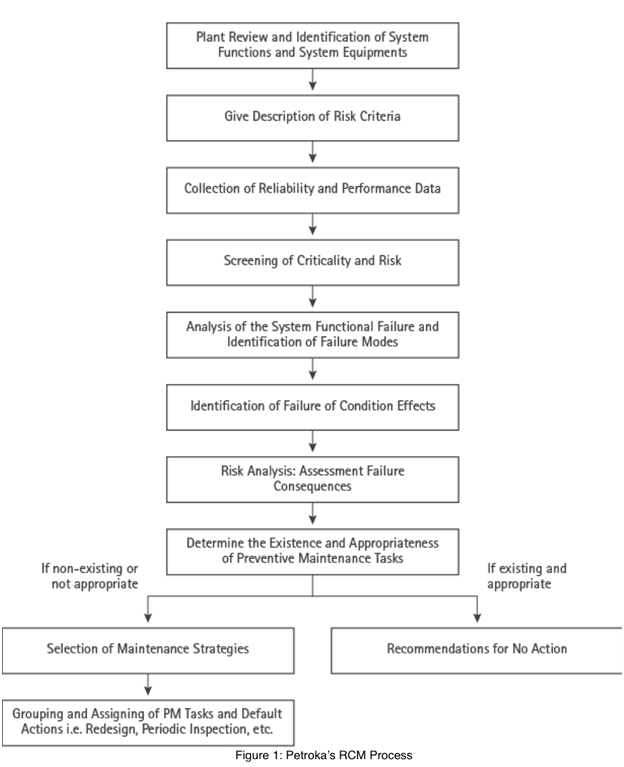

The goal of the reliability-centred maintenance (RCM) method is to provide reliability and availability at the lowest cost by developing maintenance tasks and frequencies to achieve them. RCM techniques can be used to create a cost-effective maintenance blueprint to identify risk criteria, the symptoms of system functions, and address the main causes of systems failure and equipment failure. It requires that maintenance decisions are based on maintenance requirements supported by sound technical and economic criteria.

The following are the main constituents of the RCM technique:

- System functions.

- System functional failures.

- System equipments.

- Performance standards.

- Failure modes.

- Failure effects.

- Failure consequences.

- Preventive tasks.

- Default actions.

RCM is closely related to, and takes its form from FMECA It is an approach which places emphasis on analyzing the system functions, function failures, and prevention of these failures.

The RCM method employs Proactive Maintenance techniques such as Planned Preventive Maintenance (PPM), Predictive Testing and Inspection (PT&I) and Repair (reactive maintenance) in an integrated manner to increase the probability that a component will function as required over its design life and optimize operational expenditure considerations, and to combine this with safety and environmental considerations.

Petroka employs the highest standards in our RCM studies. Our RCM execution is flexibly tailored towards your preventive maintenance needs. It is formalized in systems with decision flow diagrams, worksheets and tables. It describes the outcomes in terms of the preventive tasks and default actions. As part of our best practices for RCM, all data gathered for use will be subject to review and validation by our nominated consultant before being established in a data manual for use.

Related studies to consider are Risk Based Inspection (RBI) and Reliability Availability and Maintainability (RAM).